THACO Bus Plant.

The incredible growth of the regional automobile industries has been achieved thanks to strong and dedicated support along with domestic protection policies of the governments. From real estate perspective, policy changes in relation to the automobile industry as well as the huge potential of the four-wheel-vehicle itself is creating opportunities for acquiring more land leasing enquiries in a wide range of sector not only for industrial manufacturing but also for commercial demand such as opening showroom, car garage and warehouse.

However, real estate also has its effect on the automobile industry development. The role of industrial real estate developers herein is much emphasized as they provide not only land bank and infrastructures for automakers but more important a solution of industrial manufacturing organization. Accordingly, high production cost and low localization rate issues are partly solved by clustering automobile-related companies in a specialized industrial complex where all segments of manufacturing chain are linked together in term of geographical location as well as value chain.

In Vietnam, even though the automobile industry is far behind in developing production and assembling with other ASEAN countries, but industrial land accumulation for automobile industry has been observed in the market.

Chu Lai - Truong Hai Automobile complex in Chu Lai Open Economic Zone of Quang Nam province is a very well-known example. Recently, opening of VinFast automobile and electric vehicle manufacturing complex in Dinh Vu - Cat Hai Industrial Zone, Hai Phong City is another notable example. Both VinFast and THACO have shown their huge ambitious in dominating the domestic market by acquiring mega industrial land bank for purpose of building their own fully integrated manufacturing complex. Furthermore, their ambitious of going beyond Vietnamese border for made-in-Vietnam cars has been strongly supported by favor natural conditions for building a network of deep sea ports.

Vietnam automobile industry has still a lot to do to step in its golden time and overtake its regional rivals. The role of policy makers is considered as the most important, but the industry needs more than that. A win-win relationship herein can be set up for both the government and real estate developers. Authority nurtures the domestic industry by releasing protective policies and at the same time bring chances for industrial land developers to exploit the expansion of manufacturing as well as business demand. Real estate developers, on the other hand, offer not only for government but also automakers, logistic service vendors solutions for clustering production and supply activities into specialized automobile manufacturing complex.

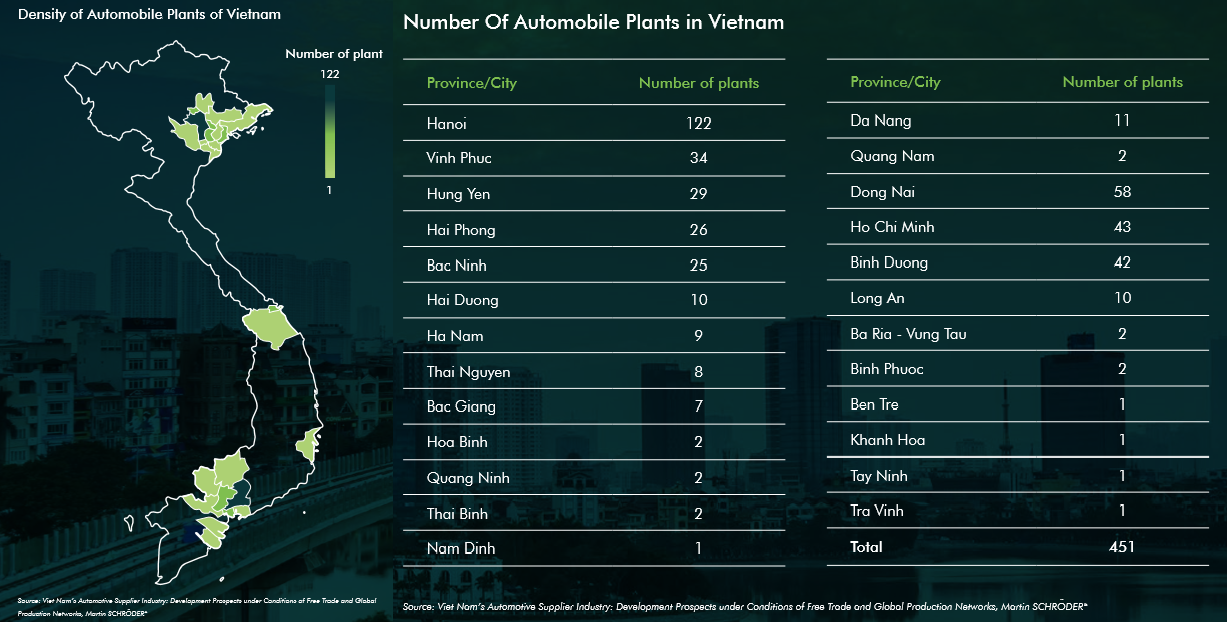

There are 451 automobile plants in Vietnam including CKD assembling and auto part making. Presence of these plants is in all three main regions of Vietnam but not equally distributed. Approximate 61% of production lines located in the North and mainly in Hanoi, Hung Yen, Vinh Phuc and Hai Phong where most of very well-known original equipment manufacturers (OEMs) place their factories such as Toyota, Honda, Ford. The South accounts for a bit more than half of total automobile plants. Ho Chi Minh City (HCMC), Dong Nai and Binh Duong are preferred locations of automakers in the South. On the other hand, Central region is the least developed region for car assembling and auto part manufacturing. It should be noticed that most of assembling and production lines are distributed in industry-oriented provinces/cities, but they are not well organized and located in automobile specialized industrial zone/cluster.

Along with the new launched VinFast Automobile Complex in Dinh Vu - Cat Hai Industrial Zone (Hai Phong City), the Chu Lai - Truong Hai Automobile Complex in Chu Lai Open Economic Zone (Quang Nam province) is one of the largest and most modern car manufacturing complexes in Vietnam. It is easily observed that these automobile complexes are in the North and Central region of Vietnam.

Chu Lai - Truong Hai Automobile Complex.

The South, meanwhile, does not have any similar scale automobile manufacturing complex. Most of automobile assembling and auto part factories/warehouses are placed in multi-industry industrial parks. In addition, production scale of each factory is also small and proportion of automobile-related factories in industrial zone is relatively low. Mechanic and automobile-related companies account for approximately 15% of total tenant in industrial zones of Binh Duong and Dong Nai. HCMC has the highest rate of mechanic and automobile-related tenant among Southern provinces (about 23%). Meanwhile, Long An’s figure is the lowest.

Per industrial land supply, four Southern industrial centers including HCMC, Binh Duong, Dong Nai and Long An currently offer about 41,868.37 hectares of industrial land to the market, of which Dong Nai accounts for 48.72% of total supply. The occupancy rate of Sothern industrial zones is also high and approximately from 80% to 95%.

Regarding automobile manufacturing expansion, the land bank required for building factories and related infrastructures, including warehouse and car testing road is normally large to install specialized production line and satisfy safety regulation. Besides, auto part making factories do not acquire that much land bank as car assembling/ manufacturing ones. Nonetheless, due to the large amount of auto parts for assembling car, manufacturing complex of these kind of factories comprises quite a lot of number of small factories and preferably placed by cluster. Hence, Southern industrial zones need to increase their limited land bank as of now for catching up with growing manufacturing demand.

More land enquiries have been generated from other auto part makers such as ISI from Europe with land area of 10,000 sqm – 25,000 sqm for equipment manufacturing in North Vietnam and Adient (USA) with 2000 sqm for automotive seating in the Central of Vietnam.

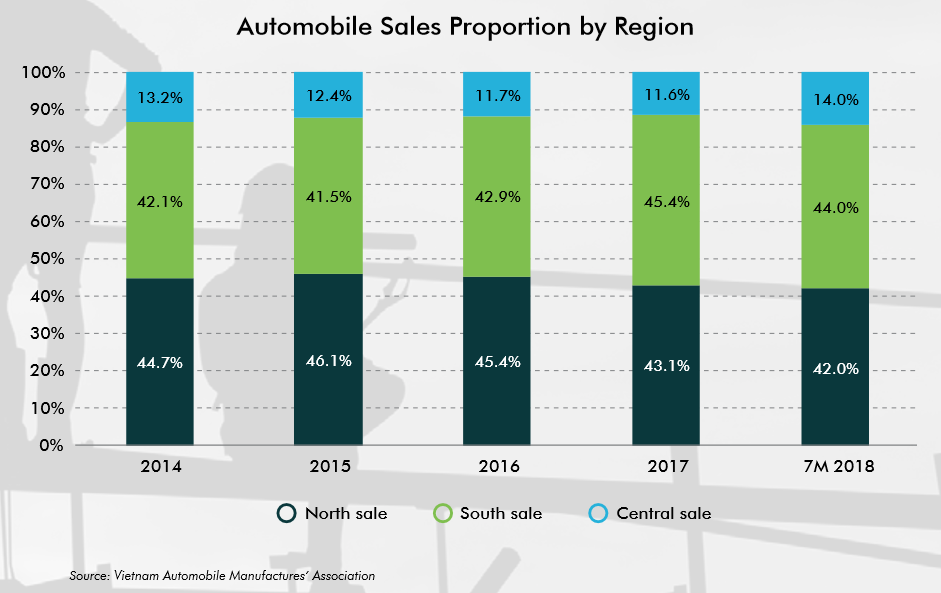

Southern region accounts for about 43.16% per year of total automobile sale of Vietnam, but the production scale and capability of Southern area (including HCMC, Dong Nai, Binh Duong and Long An) is much smaller than that of the other regions. Besides, Ho Chi Minh along with Hai Phong are main import hubs of CBU in Vietnam. Consequently, commercial and warehousing land demand (showrooms and warehouse) can be preferable in the Southern provinces and cities.

Meanwhile, the assembling cluster is mainly distributed in the North with a network of foreign OEMs factories as well as auto part manufacturing facilities. Industrial manufacturing and assembling of the North area has been accumulated thanks also to the long establishment of the industry in this region. Hanoi, Hung Yen, Vinh Phuc and Hai Duong are very well known for their factories of OEMs such as Toyota, Honda in Vietnam.

Recently, VinFast launched its mega automobile manufacturing complex in Hai Phong city with five specialized component zones (R&D zone, Automobile Manufacturing zone, Motorbike Manufacturing zone, Training zone and Localization zone). The VinFast factories establishment has strengthened the automobile assembling and manufacturing platform of the North region. Accordingly, with a strong base and rich history of car assembling and auto part production, the demand of large industrial land bank for manufacturing factories is worth considering in the North region.

The Central region, on the other hand, is the least developed area of the industry. Da Nang city and Quang Nam province are areas where density of automobile manufacturing factories is relatively high in the Central region. However, Central region also plays an important role in the Vietnamese Automobile Industry. Chu Lai - Truong Hai Automobile Complex is developed by THACO group as a full integrated automobile complex including manufacturing factories, assembling factories, supportive-industry factories, warehouses and dedicated deep sea port.

The supreme purpose of establishing automobile manufacturing complex like what VinFast and THACO have done so far is increasing localization rate and consequently cutting off production cost. Therefore, industrial land and infrastructure development demand for each region of Vietnam should be based on production and market nature to attract suitable investment.